Headstock Repair

This page shows a headstock

repair. Ishow how to do this with the most basic of tools

(well, mostly). This break was on a neck which is going to

be used for a pickup testing guitar. It's nothing great, and

I wont do a wonderful finish on it, but a repair is a repair

so,........

This is a picture of the break.

The rest of the headstock is missing. Because I don't have

the missing piece, and because there are actually multiple

breaks (there are cracks which do not show in this picture)

I will make a new piece. Also because it's a pointy headstock,

I will reshape the entire thing. The first thing I must do

is trim off all of the broken section.

This is the headstock after

trimming. The cut is very rough and not straight. I left extra

wood to allow for cleaning up the cut, Later there will be

no sign of that last tuner hole. The next task is finding

a suitable piece of wood for the repair. I selected a piece

of cherry because I had a suitable scrap around. The first

operation was to thickness the board, leaving it slightly

thick.

This picture shows the board

being thicknessed with a hand plane. it took about 5 minutes

to remove almost 1/4", and then clean it up. After the

board was thicknessed I then trimmed it so the grain would

follow more suitably. The cut was just as ugly as the first.

Now the joining faces need to be matched. to do this the boards

are "booked" (means set joining faces together and

then fold the one piece to the side so the faces to be joined

are together). I clamped the booked pieces in the vice and

trimmed them again with the hand plane. It took less than

ten minutes to get it right.

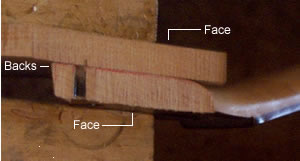

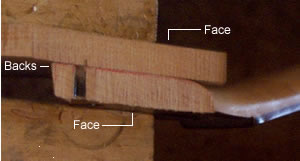

This picture shows the pieces

booked in the vice.

This picture shows the pieces

after the trimming with the handplane. To get a fit like this

it is important to check across the two pieces while trimming

to ensure they are flat across. It doesn't matter what the

angle is, because when unbooked the angles will add up to

180 degrees making the repair flat. Next is the glue up. At

this point I used a bisket joiner to reinforce the seam. This

could also be done with a router and a spline (cut slots across

the faces after glueup, square the ends of the slots w/ the

appropriate chisel and insert splines. This would be the method

I would use if the break wasn't complete, and I had both pieces)

It would have been ok without using any reinforcement because

this repair fits tightly together and is primarily along edge

grain,

This picture

shows the pieces glued and clamped . Because the faces were

angled relative to the clamping surfaces, the pieces wanted

to slide out of place, The bar clamp at the top of the picture

was used to keep the pieces in place, it isn't really "clamping".

It is not necesary to use alot of pressure with the clamps.

Allow plenty of time to cure as per the directions on the

glue bottle.

The

rest of the story....